Plough Shear Mixer

Product Details:

Plough Shear Mixer Price And Quantity

- 500000 INR

- 1 Set

Plough Shear Mixer Trade Information

- Shanghai

- Cash in Advance (CID)

- 60 Days

- Wooden Crates

- Middle East Asia Africa

Product Description

The PerMix PTS Plough mixer has been designed by our Israeli team of engineers.

This versatile Mixer can handle a wide variety of materials from dry powders, granular materials to moist solids and liquids and highly viscous material as well. An accurate mixing trace elements in the proportion of 1: 1,000,000 can be achieved through this efficient mixer.

A variety of processing applications such as compounding, fine mixing, dispersing, suspending, emulsifying and breaking down agglomerates is possible.

Applications

- Dry powder mixing: Food flavoring/additives, Sponge/cake mixes, Cosmetics, Pharmaceuticals, Cement, Powdered rubber

- Paste mixing: Biscuit creams, Dough, PVC pastes, Car body fillers/putties, Sugar/marzipan paste, Toiletry pastes, Tile adhesives and grouts

- Mixing of wet slurries: Filter cake re-slurrying, Dough, Fiber glass resin putty

- Wet granulation

- Liquid coating of powders and granules

- Fat and oil incorporation

- Vacuum drying

- Hot air drying

Construction

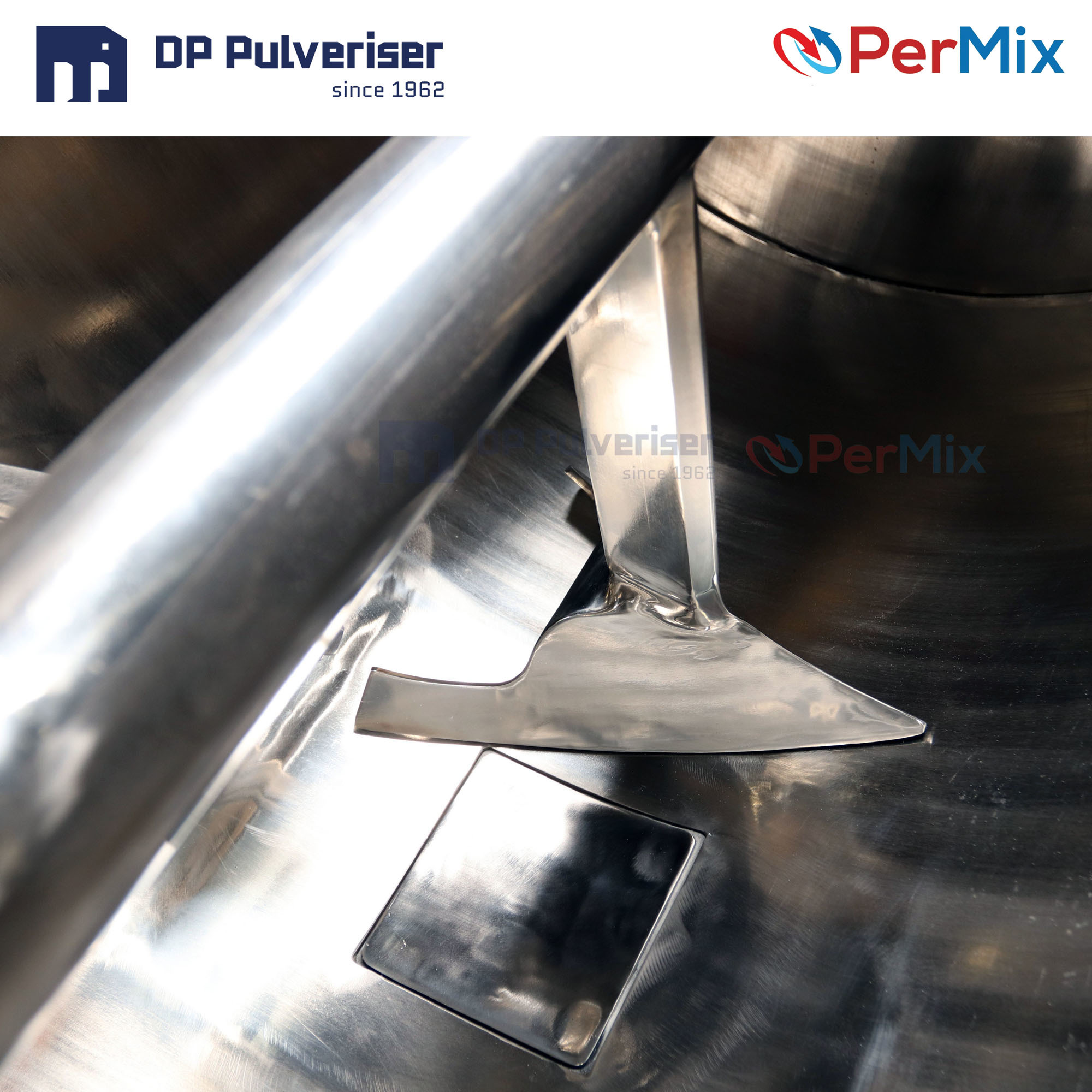

The machine consists of a centrally mounted horizontal shaft that rotates within a cylindrical container, plough shaped mixing elements that are attached to the centrally mounted shaft, special openings at the top for feeding materials, flush fitting access doors in the front of the mixer, a flush fitting discharge valve at the bottom of the mixer which is pneumatically or manually operated, and a complete drive unit.

Operating Principle

The mixing drum of a Plough Mixer is filled from 30% to 70% capacity, allowing space for individual particles to be dispersed within the main area of the mixer. The paddle-shaped mixing elements create intense axial and radial movement causing the product to move throughout the mixing area. The shape and angle, together with the adjustment and rotation of the mixing elements and the mixing drum, cause the product to be lifted off the surface of the drum wall. The product is automatically discharged while the machine is still running so that any segregation is prevented.

Special Design with Choppers

The installation of DP PerMix Multi-chopper in the basic PTS mixer enables the breaking down of agglomerates during the mixing process. Together with the mixing element, the PerMix Multi-chopper removes lumps in the initial product, chops pasty adhesives and hinders the formation of agglomeration during the moisturizing of powdered substances. The PerMix Multi-chopper is operated independently by its own motor

Lab & Pilot Model

DP PerMix is able to offer lab & pilot size plow mixers for Research & Development purpose. The small size machine is very helpful for customers when the ingredients for R&D are expensive, and to meet the budget limit at the first stage.

With the good performance of the lab & pilot mixer, it is easy to scale up for a medium size or even bigger one.

Features

Different types of mixing element for a variety of materials

DP PerMix provides mainly two types of mixing elements plough (for PTS Mixer) and paddle (for PTP Mixer). Both have their advantages: the plough shaped element can easily penetrate through the dense and thick powder or paste materials, while the paddle element can cover an even wider range of viscosity.

Construction material - MS/ SS 304/ SS 316/ GMP

Continuous operation

Vacuum drying & deaerating

Heating/Cooling jacket

Spray nozzle & Dripping pipe

Feeding & Discharging

Drive system

Extended height bases

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Machineries' category

|

D.P. PULVERISER INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry