Call : 08071794417

Call : 08071794417

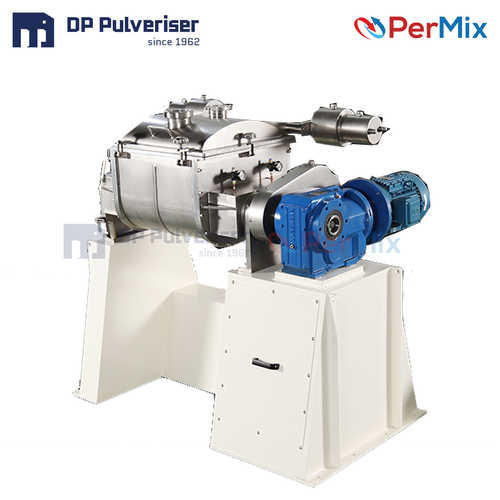

Jet Agitator

292390.00 INR

Product Details:

X

Jet Agitator Price And Quantity

- 292390.00 INR

- 1 Set

Jet Agitator Trade Information

- Cash in Advance (CID)

- 60 Days

- Wooden Crates

- Middle East Africa Asia

Product Description

A jet mixer is used where homogenizing, dispersing, suspending, emulsifying, dissolving are required. Its advantages compared with a conventional agitator are free of aeration, no floating powder, no sedimentation, no additional baffles, no flow dead zones, and very high efficient that a small motor can keep large volumes in motion.It is distinguished over ordinary blenders due to its very innovative Stator & Rotor assembly. Stator is a streamlined deflector tube fixed around the three-blade rotor. This design draws the liquid & solid into the tube and generates great turbulence there to mix and disperse those Difficult-To-Disperse powders into liquids, more cost-effective, and cutting process time up to 90%.There are two types of jet mixer available, and the difference lies in the stator. The stator can be either with or without openings.A jet mixer with a stator without openings has a stronger axial flow, because all the materials will go through the tube from the top to the bottom. But for the jet mixer with a stator with openings, some ofthe materials will go out of the tube through the openings. This makes it have some homogenizing ability.

Jet Mixers work in batch operation. Similar to High Shear Mixers, its installation is flexible enough for it to be fitted into any existing system:

- Top entry (open or closed vessel)

- Side entry

- Bottom entry

- Food & Beverage

- Cosmetics & Daily care

- Pharmaceutics & Biology

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Machineries' category

|

D.P. PULVERISER INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry