Fluidized Zone Mixer (Double Paddle Mixer)

Product Details:

Fluidized Zone Mixer (Double Paddle Mixer) Price And Quantity

- 1 Set

- 1100000 INR

Fluidized Zone Mixer (Double Paddle Mixer) Trade Information

- Shanghai

- Cash in Advance (CID)

- 60 Days

- Wooden Crates

- Middle East Africa Asia

Product Description

Advantages

- Fast & gentle mixing, typical mixing time is 10-60 seconds for dry, free-flowing materials

- Free particle movement

- Minimal heat and low shear for shear and heat sensitive materials (Due to the fact that low friction without shear in this non-gravity zone is generated, this makes the PerMix PFB series Twin-shaft Paddle Mixer an ideal machine for fragile products that cant tolerate rough handling, even flakes or spray dried bodies remaining intact after mixing.)

- Easy cleaning and hygienic design with minimal blind corners

- Low maintenance

- Fast discharging & reduced segregation

Working Principle

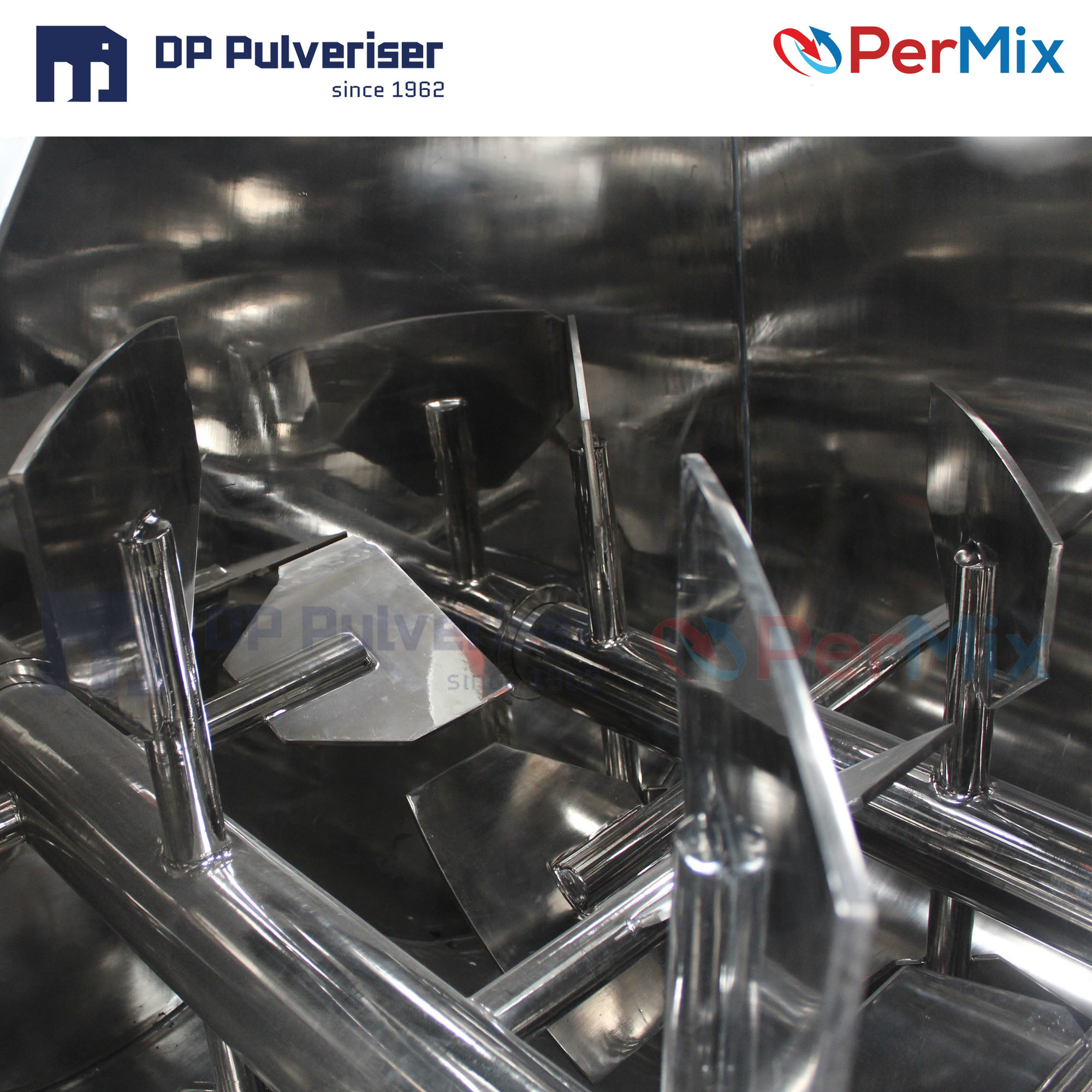

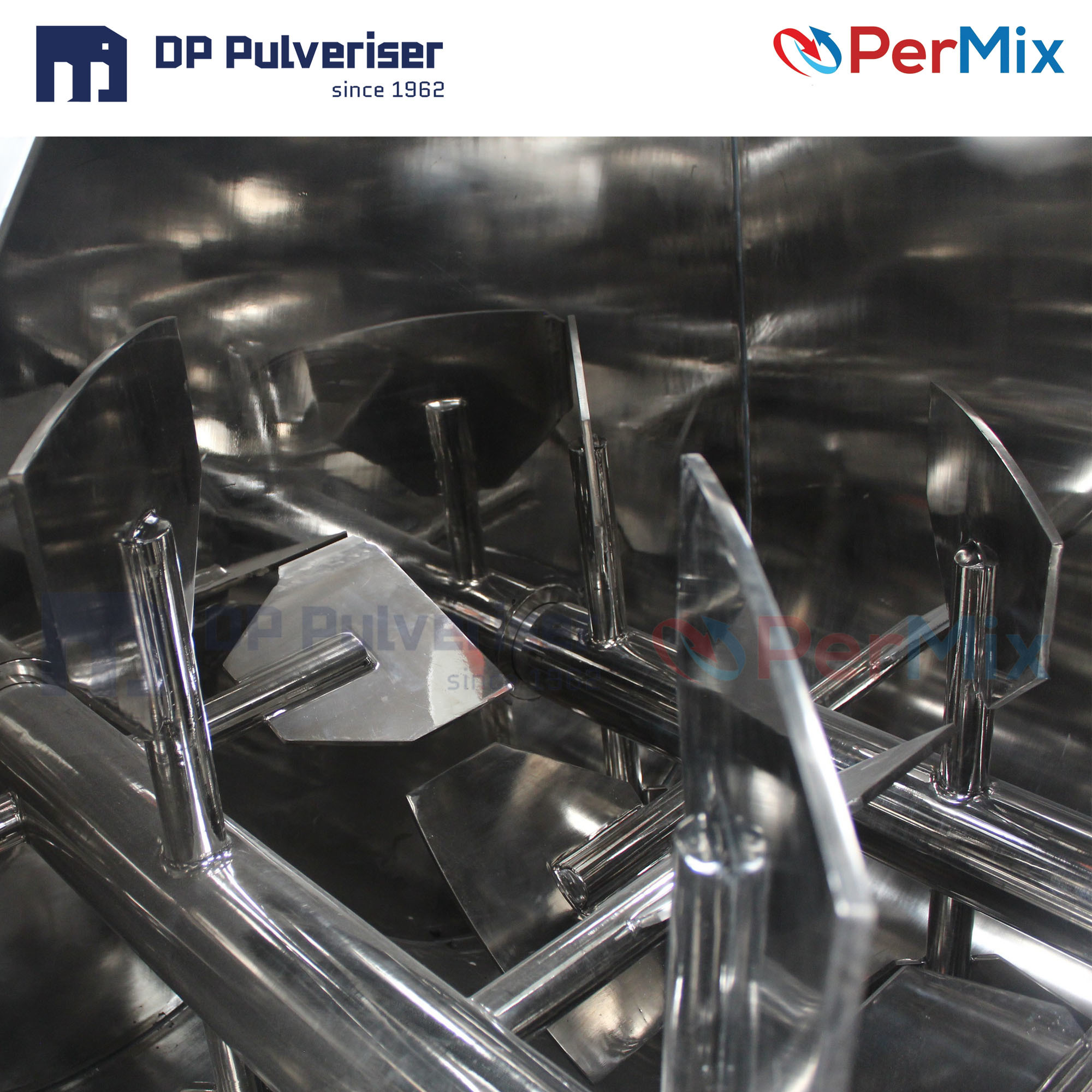

The DP PerMix PFB series Twin Paddle Mixer consists of paddles with special angles that are mounted on twin shafts in a W shaped trough. During operation, the two shafts are rotating in opposite direction.

The paddles sweep the entire bottom of both troughs, and materials are lifted floating between the two shafts (as zero-gravity zone) by the centrifugal force generated by the paddles.

At this weightless zone, mixing of materials of different density is easy and fast because material particle can move freely and randomly, regardless of particle size and density. This brings a rapid and highly homogenous mixing.

Special Designs with Overhead Chopper:

Although the DP PerMix PFB series Twin-shaft Paddle Mixer is featured by its gentle mixing at the weightless zone, it can also achieve rough mixings with additional PerMix Pin Milling Bars to be installed on the top of the paddles.

The PerMix Pin Milling Bars are two rapidly rotating bars with pins and a stationary shroud, which introduce high shear force onto the materials during mixing to break soft lumps and agglomerates. In this case, a fill level of 140% of normal capacity is required.

Applications

- Chemical Industry

Detergents, Color pigments, Fertilizers, Explosives, Boric acid, Carbon, Fly ash, Fungicides, Soda ash

- Building Industry

Dry mortar, Blended cements, Tile adhesives/grouting, Brick facings, Cement & Fibers, Flooring materials, Joint compounds, Road lining materials

- Environmental Applications

Fly ash conditioning, Filter dust treatment, Sewage sludge, Food waste

- Feed Industry

Animal feed, Mineral premixes, Aqua / fish feed, Pet food, Dairy additives

- Food Industry

Instant drinks/soups, Infant milk powder, Flour/bread/bakery mixes, Frozen vegetables, Treatment of spices

- Pharmaceutical Industry

Vitamin mixes, Medical mixes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Machineries' category

|

D.P. PULVERISER INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry